Overlap Film Wrappers

The most versatile machines available

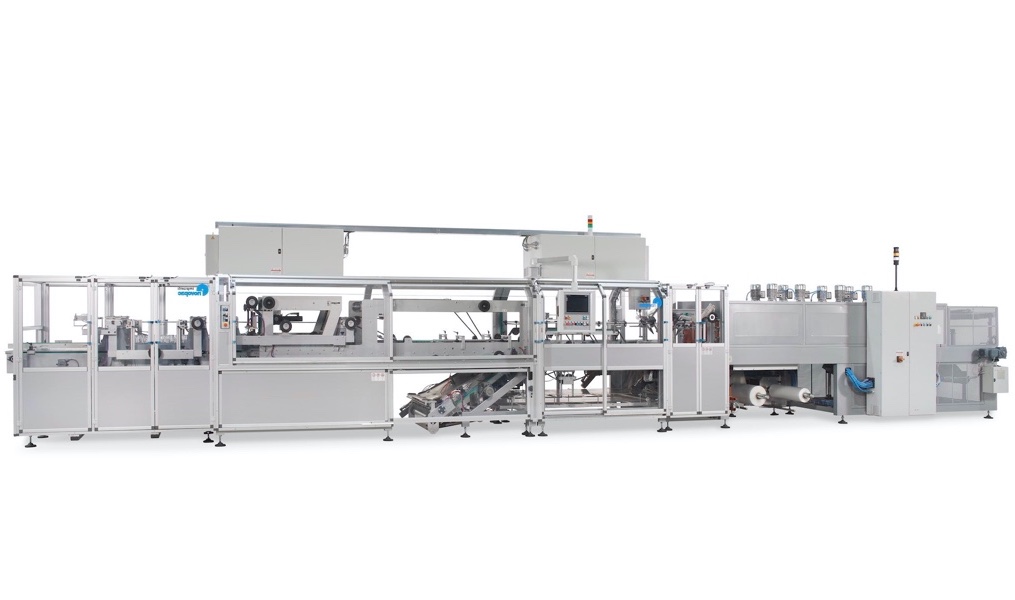

This range of machines represent the solutions for medium and high speed shrink-wrapping projects. It is a development of the original core equipment stream manufacturing that has made Novopac a worldwide leader in the packaging industry. These lines are distinguished by robust design and build, leading to reliability through a technological synchronised film overlap system and a safe and efficient shrink tunnel. The lines are designed for the collation and packing of products in multi-packs to be protected from dust, dirt, and humidity. Flexible collating systems are available depending on the nature, shape and rigidity of the product.

All equipment is built according to the strict EC standards (European safety rules) and achieve the highest performance to meet the most demanding quality requirements.

Packaging

CFM+LA+BM

Compact All-in-1 Integrated Equipment

50-100 packs/min

Film Only

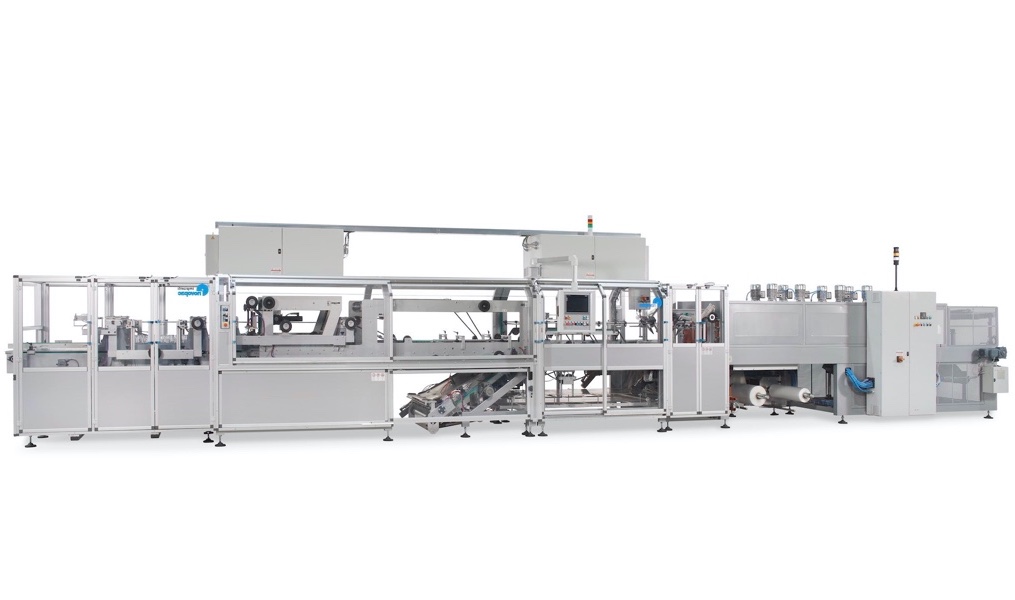

CFM S+LA+BM

Compact All-in-1 Integrated Equipment

50-100 packs/min

Film + Cardboard Support Pad

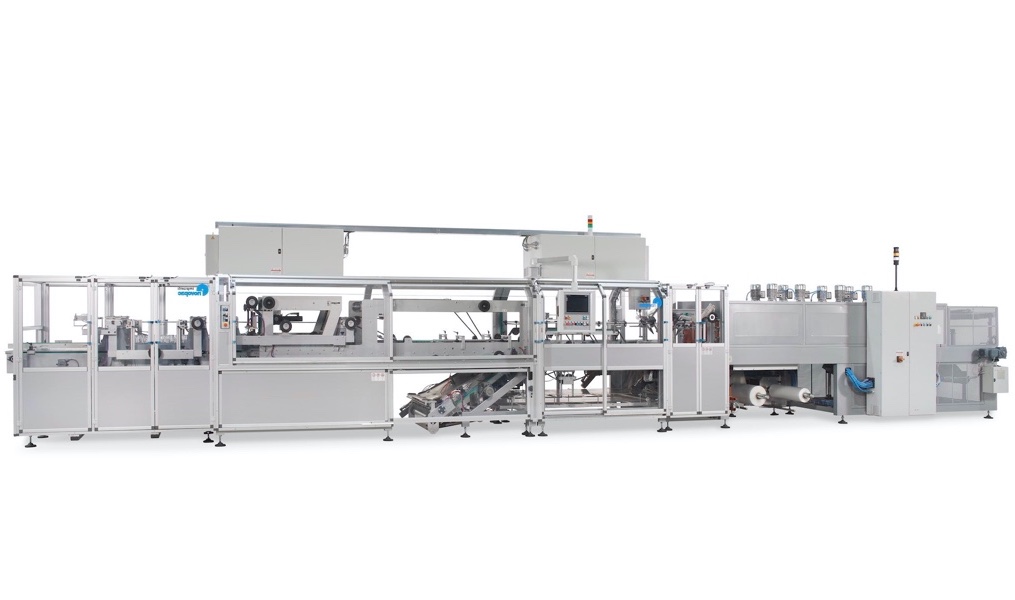

CFM WR+LA+BM

Compact All-in-1 Integrated Equipment

50-100 packs/min

Film + Wrap Around Cardboard Tray

Products

This series is composed of medium and high speed shrink-wrappers with continuous working process. They feature synchronised film overlapping suitable for collating and wrapping most kinds of bottles, cans, jars and pots in multi-packs, thus achieving protection from dust, dirt, water/humidity among other pollutants.

For highest speeds requirements these lines can be manufactured in twin stream (dual lane version).

Characteristics

- Automatic in-line infeed, on single lane or in mass flow

- Reliable synchronised film overlap system

- Completely safe shrinking operation

- Quick and easy changeover

- Mechanically robust and reliable design.

- The overlap and shrink system (“LA + BM”) is easy-to-link to wrap-around machines (link VF series)

-

benefits

→ Reliable and efficient machines based on over 40 years of experience

→ Ustomised manufacturing to suit any special customer requirement.

→ Easy integration of other secondary packaging processes for additional packaging alternatives (e.g. labelling, ink jet, although not supplied by us).

→ Special design of the Shrink-Tunnel for maximum product safety; the heat is absorbed by the film, the product remains cold (successfully validated for food, frozen and flammable products).

→ Final packing visual quality aimed either for Industrial or massive consumption products distribution.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service applied.

OTHER PACKERS

FILM WRAPPERS

MORE LINKS

End of line Projects

Videos

Technical assistance programs